RFID Tool Tracking System

RFID tool tracking system using RFID asset tags helps organizations to locate assets faster and having high visibility across the entire organization.RFID tool tracking is a part of an RFID asset tracking system to manage assets completely.

It’s a crucial requirement for organizations to have the right tool at the right time. Tool tracking is a critical aspect of the manufacturing, engineering, construction, and aerospace industries.RFID tool tracking can be integrated with RFID employee tracking system to track tools borrowed by, used by any employee in the organization, and also it will reveal who owns the tool for a longer time and where they left recently.

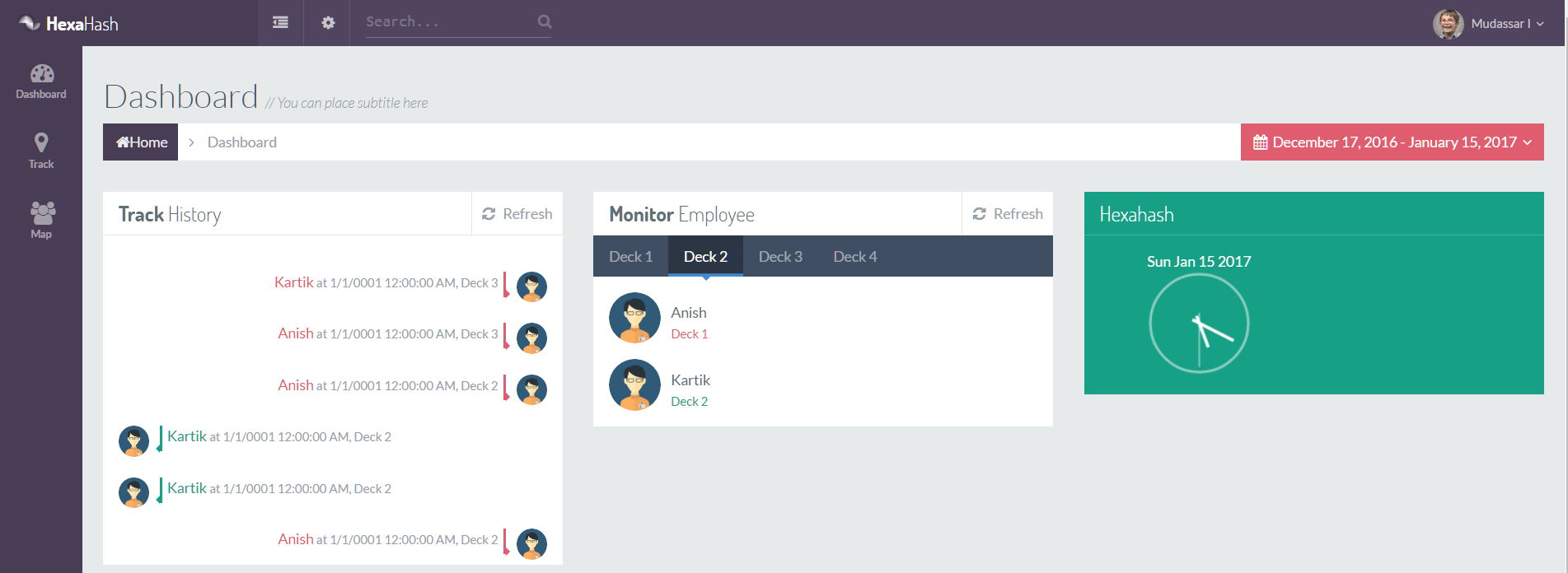

HexaTrack is the choice of many industries around the world for the best and efficient RFID tool tracking systems. Hexahash RFID tool tracking solution uses state of the art technologies to help companies to have a real-time location of the tools, maintenance history of the equipment, and tool inventory. Hexahash believes in innovation, which can provide a unique solution to meet the requirement of customers.

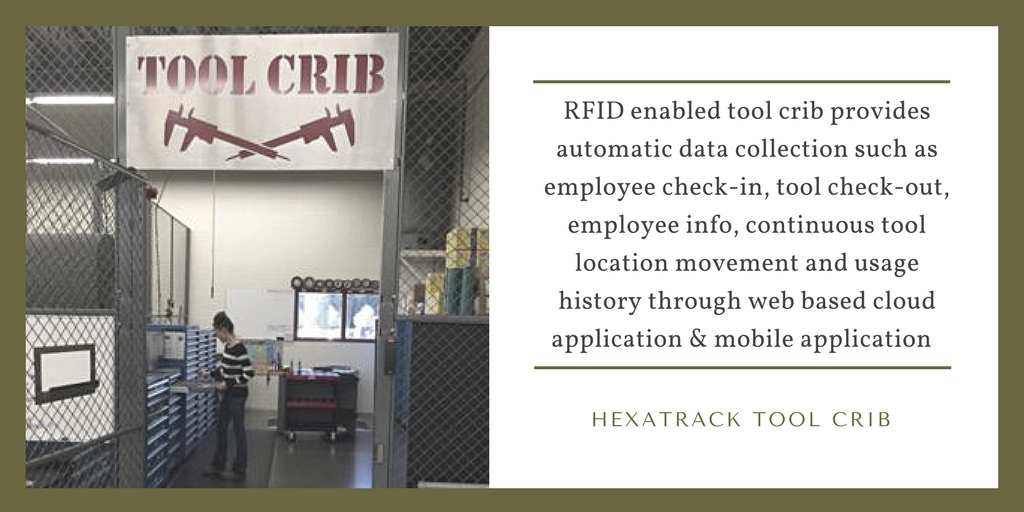

RFID (radio frequency identifier) tags are small tags that can be read by wireless, non-contact readers. These RFID tags used for our tool tracking are designed to withstand very harsh conditions and met the unique needs of every organization. RFID tool tracking with RFID tags is more efficient and time saving for the industries. It will increase the efficiency of the production and maintenance process into many folds. Tool crib inventory software of Hexahash provides easy to use interface to handle tools across locations of the organization. Automated tool tracking system empower industries to improve their business process and productivity

HexaTrack RFID based RTLS solution can help you streamline your processes and optimize your business. It reduces your worry about the costly waste of time or money arising from lack of control, employee hoarding, stock outs, lost tools, FOD or theft of equipment and inventory.

RFID Tool Tracking

FOD Control

Maintenance

Tool Room Management

The only tool tracking system you’ll ever need

Cloud Application for consumable MRO and indirect items. Track issuance, usage per employee or department, automatic or manually initiated replenishment ordering from multiple suppliers, run reports, print barcode labels and manage one or more cribs, stores, and POU areas from a web browser anywhere using web pages or with specific features through smartphones and mobile barcode scanners, mobile RFID readers and handheld RFID readers

Tool Crib Software

Visual Tool Control